The Science Behind Nanofiber Filtration: How It Works & Why It Matters

Air may look clean, but it often carries microscopic particles that pose real risks to respiratory health. From pollution and wildfire smoke to allergens and airborne pathogens, many of today’s most harmful airborne threats are invisible to the naked eye. This is where filtration science becomes critical. Among modern filtration technologies, nanofiber filtration stands out as one of the most effective and practical solutions for everyday clean-air protection.

Understanding how nanofiber filtration works—and why it matters—helps explain why it is increasingly seen as the future of respiratory protection.

What Is Nanofiber Filtration?

Nanofibers are extremely thin fibers, typically measured in nanometers—thousands of times thinner than a human hair. When these fibers are layered together, they form a dense yet breathable filtration matrix capable of capturing microscopic particles that traditional materials often miss.

Unlike bulky filter layers that rely on thickness alone, nanofiber filters use precision engineering at the microscopic level. This allows them to block fine particles efficiently while still permitting airflow, which is essential for comfort and consistent use.

How Traditional Filters Capture Particles

To understand the advantage of nanofiber filtration, it helps to look at how conventional filters work. Traditional mask materials generally rely on one or more of the following mechanisms:

- Mechanical blocking, where larger particles are physically stopped by the fibers

- Electrostatic attraction, where charged fibers attract and trap particles

- Layer density, where thicker materials increase the chance of particle capture

While these methods can be effective, they often come with trade-offs. Thicker or denser layers can restrict airflow, making masks uncomfortable to wear for long periods. Electrostatic charge can diminish over time, especially with moisture and repeated use.

How Nanofiber Filtration Works Differently

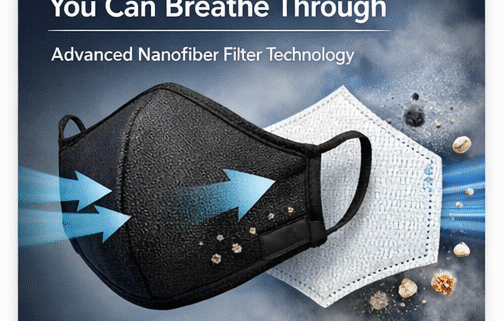

Nanofiber filtration improves on these methods by increasing efficiency without relying on bulk or heavy materials. The extremely small diameter of nanofibers creates a large surface area within the filter. This allows particles to be captured through multiple physical mechanisms simultaneously, including interception, diffusion, and inertial impaction.

Because the fibers are so thin and evenly distributed, air can pass through more easily compared to traditional dense filters. This results in lower breathing resistance while maintaining high filtration performance.

In simple terms, nanofiber filters create a tighter, smarter net—one that catches harmful particles without making breathing feel labored.

Why PM2.5 Particles Are a Major Concern

One of the biggest challenges in air filtration is fine particulate matter, commonly referred to as PM2.5. These particles are smaller than 2.5 microns and are produced by sources such as vehicle emissions, industrial pollution, wildfire smoke, and certain indoor activities.

PM2.5 particles are small enough to penetrate deep into the lungs and, in some cases, enter the bloodstream. Exposure has been linked to respiratory irritation, inflammation, cardiovascular strain, and worsened asthma symptoms.

Nanofiber filtration is particularly effective against PM2.5 because the fiber structure is designed to capture particles at this microscopic scale—where traditional materials often struggle.

Breathability: The Key to Real-World Protection

Filtration efficiency alone does not guarantee protection. A mask that is difficult to breathe through is unlikely to be worn consistently, especially during long commutes, workdays, or travel.

Nanofiber filtration addresses this challenge by balancing particle capture with airflow. Because air moves more freely through the filter, users experience less resistance, heat buildup, and fatigue. This encourages proper, consistent wear—one of the most important factors in reducing real-world exposure.

Fit and Seal: Completing the System

Even the most advanced filter cannot perform effectively if air leaks around it. Proper fit ensures that inhaled air passes through the nanofiber layer rather than escaping through gaps at the nose, cheeks, or chin.

Modern mask designs that incorporate nanofiber filtration typically emphasize ergonomic shaping, adjustable features, and soft contact materials. These elements work together to maintain a secure seal without discomfort, maximizing filtration performance in everyday use.

Why Nanofiber Filtration Matters Beyond Emergencies

Historically, masks were associated primarily with emergencies—wildfires, pollution spikes, or disease outbreaks. However, air quality challenges are now more frequent and persistent.

Nanofiber filtration supports a shift from reactive to preventive respiratory care. By reducing daily exposure to fine particles, allergens, and airborne irritants, individuals can protect long-term lung and cardiovascular health, not just respond to short-term threats.

This makes nanofiber masks suitable for a wide range of everyday scenarios, including commuting, travel, indoor gatherings, allergy season, and poor air quality days.

A Smarter Standard for Clean Air

As awareness of air quality grows, expectations for protective solutions are rising. People want protection that is effective, comfortable, reusable, and suited for daily life—not just emergencies.

Nanofiber filtration meets these expectations by combining advanced science with practical design. It represents a smarter, more sustainable standard for clean-air protection—one that aligns with modern health priorities and real-world needs.

Why the Science Matters

Understanding the science behind nanofiber filtration builds trust and clarity. It explains why some masks perform better than others and why comfort and filtration must work together.

Clean air is fundamental to health. As environmental challenges continue to evolve, technologies rooted in sound science—like nanofiber filtration—will play a critical role in protecting how we breathe, today and in the future.